-

Table of Contents – Strategies

- Technology

- Communication-in-quality-control-aEaHHxBaEM”>Importance Of Clear Communication In Quality Control

- Best Practices For Training Warehouse Staff On Quality Standards

- Utilizing Visual Aids To Enhance Understanding Of Quality Control

- Regular Feedback Mechanisms For Quality Control Compliance

- Creating A Culture Of Quality Awareness Among Warehouse Employees

- Leveraging Technology For Effective Quality Control Communication

- Strategies For Addressing Common Misunderstandings In Quality Standards

- Q&A

- Conclusion

This article on Warehouse quality control communication strategies also touches on related topics like Quality Control, Strategies, Communication, Technology.

“Empowering Warehouse Excellence: Clear Communication of Quality Control Standards.” Quality Control is a foundational topic here. Communication is equally relevant.

Effective communication of quality control standards to warehouse staff is crucial for maintaining product integrity and operational efficiency. Clear and concise communication ensures that all team members understand the expectations and procedures necessary to uphold quality standards. This involves not only outlining the specific quality control measures but also providing training and resources to empower staff in their roles. By fostering an environment of open dialogue and continuous feedback, organizations can enhance compliance, reduce errors, and ultimately improve overall performance in the warehouse.

Importance Of Clear Communication In Quality Control

In the realm of quality control, the significance of clear communication cannot be overstated. Effective communication serves as the backbone of any successful quality control program, particularly in a warehouse setting where the stakes are high, and the margin for error is slim. When warehouse staff are well-informed about quality control standards, they are empowered to take ownership of their roles, leading to enhanced productivity and a culture of excellence. This empowerment begins with a clear understanding of what is expected of them, which can only be achieved through effective communication.

To illustrate the importance of clear communication, consider the various tasks that warehouse staff undertake daily. From receiving shipments to picking and packing orders, each step in the process is critical to maintaining quality standards. If employees are unclear about these standards, the likelihood of errors increases significantly. For instance, if a team member is unsure about the criteria for inspecting incoming goods, they may overlook defects that could compromise the quality of the final product. This not only affects customer satisfaction but can also lead to costly returns and damage to the company’s reputation. Therefore, it is essential that quality control standards are communicated in a straightforward and accessible manner.

Moreover, clear communication fosters a sense of accountability among warehouse staff. When employees understand the quality control standards and the rationale behind them, they are more likely to take pride in their work. This sense of ownership can lead to proactive behavior, where staff members actively seek to uphold and even exceed quality standards. For example, if a warehouse worker knows that their role directly impacts customer satisfaction, they are more likely to double-check their work and report any discrepancies. This proactive approach not only enhances the quality of the products being handled but also cultivates a positive work environment where everyone is aligned toward a common goal.

In addition to fostering accountability, effective communication also plays a crucial role in training and onboarding new staff. When new employees are brought into the fold, it is vital that they receive comprehensive training on quality control standards. This training should not only cover the technical aspects of quality control but also emphasize the importance of these standards in the broader context of the company’s mission and values. By doing so, new hires can quickly grasp the significance of their roles and how they contribute to the overall success of the organization. This understanding can lead to higher retention rates and a more engaged workforce.

Furthermore, ongoing communication about quality control standards is essential for continuous improvement. As processes evolve and new challenges arise, it is important to keep warehouse staff informed about any changes to quality control protocols. Regular meetings, updates, and feedback sessions can help ensure that everyone is on the same page and that any issues are addressed promptly. This open line of communication not only helps to maintain high standards but also encourages a culture of collaboration and innovation, where employees feel comfortable sharing their insights and suggestions for improvement.

In conclusion, the importance of clear communication in quality control cannot be underestimated. By ensuring that warehouse staff are well-informed about quality standards, organizations can foster a culture of accountability, enhance employee engagement, and drive continuous improvement. Ultimately, when everyone is aligned and committed to upholding quality standards, the entire organization benefits, leading to greater customer satisfaction and long-term success.

Best Practices For Training Warehouse Staff On Quality Standards

Training warehouse staff on quality control standards is a critical component of ensuring operational excellence and maintaining high product standards. To achieve this, organizations must adopt best practices that not only convey the necessary information but also inspire a culture of quality among employees. One of the most effective strategies is to create a comprehensive training program that combines theoretical knowledge with practical application. This dual approach allows staff to understand the importance of quality standards while also seeing how these standards are implemented in their daily tasks.

To begin with, it is essential to develop clear and concise training materials that outline the quality control standards relevant to the warehouse environment. These materials should be easily accessible and presented in a format that caters to various learning styles. For instance, incorporating visual aids such as infographics and videos can enhance understanding, while hands-on demonstrations can solidify this knowledge. By providing diverse resources, organizations can ensure that all employees, regardless of their learning preferences, grasp the critical aspects of quality control.

Moreover, engaging employees in interactive training sessions can significantly enhance retention and understanding. Rather than relying solely on lectures, incorporating group discussions, role-playing scenarios, and problem-solving exercises can foster a more dynamic learning environment. This interactive approach not only encourages participation but also allows staff to share their insights and experiences, creating a sense of ownership over the quality control process. When employees feel that their contributions are valued, they are more likely to take pride in their work and adhere to quality standards.

In addition to initial training, ongoing education is vital for maintaining high-quality standards in the warehouse. Regular refresher courses and updates on new quality control protocols can help reinforce the importance of these standards and keep staff informed about any changes. Furthermore, organizations should consider implementing a mentorship program where experienced employees can guide newer staff members. This not only facilitates knowledge transfer but also fosters a supportive work environment where employees feel empowered to ask questions and seek guidance.

Another best practice is to establish clear performance metrics related to quality control. By setting specific, measurable goals, employees can better understand the expectations placed upon them. Regularly reviewing these metrics and providing constructive feedback can motivate staff to improve their performance continually. Celebrating achievements, whether big or small, can also inspire a culture of quality. Recognizing individuals or teams who consistently meet or exceed quality standards reinforces the message that quality is a shared responsibility and a key component of the organization’s success.

Furthermore, fostering open communication channels is crucial for effective training on quality standards. Encouraging staff to voice their concerns or suggestions regarding quality control processes can lead to valuable insights and improvements. When employees feel heard, they are more likely to engage with the training material and apply what they have learned in their daily tasks. This collaborative approach not only enhances the training experience but also cultivates a sense of community within the warehouse.

Ultimately, training warehouse staff on quality control standards is not merely about compliance; it is about instilling a mindset of excellence. By implementing these best practices, organizations can create an environment where quality is prioritized, and employees are inspired to take ownership of their roles. As a result, the warehouse becomes not just a place of work but a hub of continuous improvement, where every team member contributes to the overarching goal of delivering exceptional products and services.

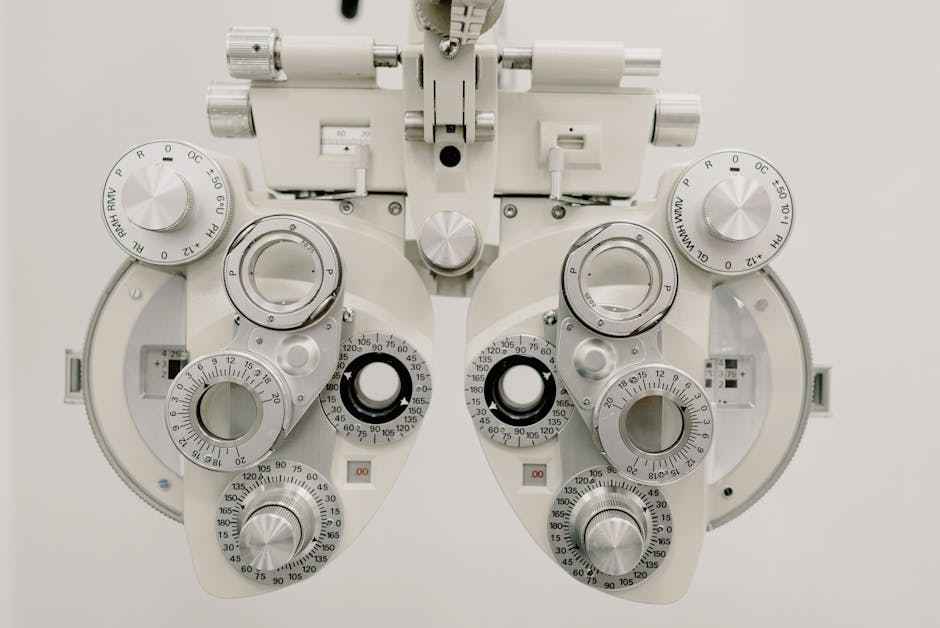

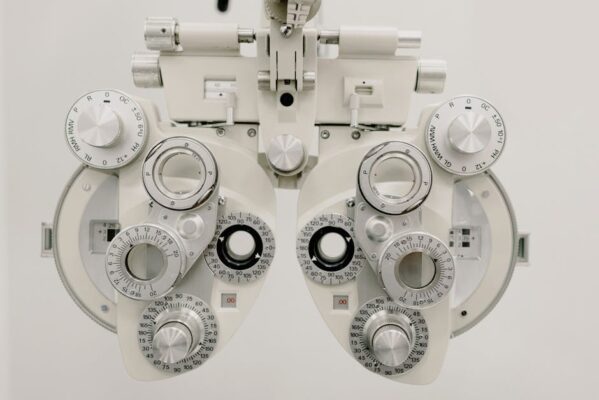

Utilizing Visual Aids To Enhance Understanding Of Quality Control

In the realm of quality control, effective communication is paramount, especially when it comes to conveying standards to warehouse staff. One of the most impactful methods to enhance understanding is through the use of visual aids. Visual aids serve as powerful tools that can bridge the gap between complex quality control concepts and the practical application of these standards in a warehouse setting. By incorporating visual elements, organizations can foster a clearer understanding among employees, ultimately leading to improved compliance and performance.

To begin with, visual aids can simplify intricate information, making it more accessible to all staff members, regardless of their educational background or experience level. For instance, infographics can distill essential quality control processes into easily digestible formats. By presenting information visually, employees can quickly grasp the key points without feeling overwhelmed by text-heavy documents. This approach not only enhances comprehension but also encourages engagement, as staff members are more likely to interact with visually appealing materials.

Moreover, the use of charts and diagrams can illustrate workflows and procedures in a way that is both intuitive and memorable. For example, a flowchart depicting the steps involved in a quality inspection process can guide employees through each stage, ensuring that they understand their responsibilities and the importance of each task. By visualizing the process, staff can see how their actions contribute to the overall quality of the products being handled, fostering a sense of ownership and accountability.

In addition to flowcharts, photographs and videos can serve as effective visual aids in training sessions. By showcasing real-life examples of quality control standards in action, employees can better understand what is expected of them. For instance, a video demonstrating proper handling techniques for fragile items can provide a clear reference point, allowing staff to visualize the correct methods and apply them in their daily tasks. This not only reinforces learning but also helps to establish a culture of quality within the warehouse.

Furthermore, incorporating color-coded systems can enhance the effectiveness of visual aids. By using different colors to signify various quality control standards or procedures, employees can quickly identify critical information at a glance. For example, a color-coded labeling system for storage bins can indicate which items meet quality standards and which do not, streamlining the sorting process and reducing the likelihood of errors. This simple yet effective strategy can significantly improve operational efficiency while ensuring that quality remains a top priority.

As organizations strive to communicate quality control standards effectively, it is essential to consider the diverse learning styles of warehouse staff. Some individuals may respond better to visual stimuli, while others may prefer hands-on experiences or verbal instructions. By integrating a variety of visual aids into training programs, companies can cater to these different preferences, ensuring that all employees have the opportunity to learn and succeed.

Ultimately, the goal of utilizing visual aids in communicating quality control standards is to create an environment where employees feel empowered and informed. When staff members understand the importance of quality control and have the tools to implement it effectively, they are more likely to take pride in their work and contribute to the overall success of the organization. By investing in visual communication strategies, companies not only enhance understanding but also inspire a culture of excellence that resonates throughout the warehouse. In this way, visual aids become more than just tools; they become catalysts for a shared commitment to quality and continuous improvement.

Regular Feedback Mechanisms For Quality Control Compliance

In the realm of quality control, the importance of regular feedback mechanisms cannot be overstated, especially when it comes to ensuring that warehouse staff are aligned with established standards. Effective communication of these standards is crucial, as it not only fosters a culture of accountability but also empowers employees to take ownership of their roles in maintaining quality. By implementing structured feedback systems, organizations can create an environment where continuous improvement is not just encouraged but becomes a fundamental aspect of daily operations.

To begin with, regular feedback serves as a vital link between management and warehouse staff. It provides an opportunity for supervisors to recognize and celebrate compliance with quality control standards while also addressing areas that may require improvement. This two-way communication is essential; when employees receive constructive feedback, they are more likely to understand the rationale behind quality control measures. Consequently, they can better appreciate how their individual contributions impact the overall success of the organization. This understanding fosters a sense of pride and responsibility among staff, motivating them to adhere to quality standards consistently.

Moreover, establishing a routine for feedback can significantly enhance the effectiveness of quality control initiatives. For instance, weekly or bi-weekly check-ins can be scheduled to discuss performance metrics, share insights, and highlight best practices. During these sessions, it is beneficial to encourage open dialogue, allowing employees to voice their concerns and suggestions. This collaborative approach not only strengthens relationships between staff and management but also cultivates a sense of belonging and teamwork. When employees feel heard and valued, they are more likely to engage actively in quality control processes, leading to improved compliance and overall performance.

In addition to scheduled meetings, leveraging technology can further streamline feedback mechanisms. Digital platforms can facilitate real-time communication, enabling warehouse staff to receive immediate feedback on their performance. For example, mobile applications can be utilized to report quality issues or compliance breaches, allowing for swift corrective actions. This immediacy not only helps in addressing problems before they escalate but also reinforces the importance of adhering to quality standards. By integrating technology into the feedback process, organizations can create a more responsive and agile quality control system.

Furthermore, it is essential to recognize that feedback should not solely focus on compliance failures. Celebrating successes is equally important, as it reinforces positive behaviors and motivates staff to maintain high standards. Acknowledging individual and team achievements can be done through various means, such as recognition programs or informal shout-outs during team meetings. By highlighting successes, organizations can create a positive feedback loop that encourages continuous adherence to quality control standards.

Ultimately, the goal of regular feedback mechanisms is to create a culture of quality within the warehouse environment. When employees understand that quality control is a shared responsibility, they are more likely to take proactive steps to ensure compliance. This collective commitment not only enhances operational efficiency but also contributes to customer satisfaction and brand reputation. As organizations invest in effective communication strategies and feedback systems, they lay the groundwork for a resilient workforce that is dedicated to upholding quality standards. In this way, regular feedback becomes not just a tool for compliance but a catalyst for inspiration, driving everyone towards excellence in their roles.

Creating A Culture Of Quality Awareness Among Warehouse Employees

Creating a culture of quality awareness among warehouse employees is essential for any organization striving for excellence in its operations. When employees understand the importance of quality control standards, they become more engaged and motivated to uphold these standards in their daily tasks. This cultural shift begins with effective communication, which serves as the foundation for fostering a shared commitment to quality.

To initiate this transformation, it is crucial to establish clear and consistent messaging about quality control standards. This involves not only outlining the specific standards that need to be met but also explaining the rationale behind them. When employees grasp the significance of these standards, they are more likely to internalize them and see their role in the bigger picture. For instance, discussing how quality impacts customer satisfaction and the overall success of the company can inspire employees to take ownership of their responsibilities.

Moreover, it is important to create an environment where open dialogue is encouraged. Employees should feel comfortable discussing quality-related issues, asking questions, and providing feedback. This can be achieved through regular meetings, training sessions, and informal check-ins. By fostering a culture of transparency, employees will feel valued and empowered to contribute to quality improvement initiatives. This sense of ownership not only enhances their commitment to quality but also promotes teamwork, as employees collaborate to identify and solve quality-related challenges.

In addition to open communication, recognizing and celebrating quality achievements can significantly boost morale and reinforce the importance of quality awareness. When employees see that their efforts to maintain high standards are acknowledged, they are more likely to remain motivated and engaged. Implementing a recognition program that highlights individuals or teams who excel in quality control can serve as a powerful incentive. This not only reinforces the desired behaviors but also creates role models within the organization, inspiring others to follow suit.

Training and development play a pivotal role in cultivating a culture of quality awareness. Providing employees with the necessary tools and knowledge to understand and implement quality control standards is essential. This can include workshops, hands-on training, and access to resources that outline best practices. By investing in their development, organizations demonstrate their commitment to quality and empower employees to take pride in their work. Furthermore, ongoing training ensures that employees stay updated on any changes to quality standards, fostering a sense of continuous improvement.

As organizations strive to create a culture of quality awareness, it is vital to lead by example. Leadership should embody the principles of quality control and demonstrate their commitment through their actions. When employees see their leaders prioritizing quality, they are more likely to adopt similar attitudes. This alignment between leadership and staff creates a cohesive environment where quality is not just a set of standards but a shared value that everyone upholds.

Ultimately, creating a culture of quality awareness among warehouse employees requires a multifaceted approach that emphasizes clear communication, open dialogue, recognition, training, and strong leadership. By fostering an environment where quality is celebrated and prioritized, organizations can inspire their employees to take ownership of their roles in maintaining high standards. This cultural shift not only enhances operational efficiency but also contributes to a more engaged and motivated workforce, ultimately leading to greater success for the organization as a whole. In this way, quality becomes not just a goal but a way of life within the warehouse, driving continuous improvement and excellence in every aspect of operations.

Leveraging Technology For Effective Quality Control Communication

In today’s fast-paced logistics environment, effective communication of quality control standards to warehouse staff is paramount for maintaining operational excellence. Leveraging technology can significantly enhance this communication, ensuring that every team member is aligned with the organization’s quality objectives. By integrating advanced tools and platforms, companies can create a seamless flow of information that empowers employees and fosters a culture of quality.

One of the most impactful ways to utilize technology is through the implementation of mobile applications designed specifically for warehouse operations. These applications can serve as real-time communication channels, allowing staff to access quality control standards, guidelines, and updates instantly. For instance, when a new quality protocol is introduced, it can be disseminated through push notifications, ensuring that all employees are informed simultaneously. This immediacy not only reduces the risk of miscommunication but also reinforces the importance of adhering to quality standards.

Moreover, utilizing cloud-based platforms can facilitate collaborative efforts among team members. By centralizing quality control documents and resources, employees can easily reference the latest procedures and best practices. This accessibility encourages a proactive approach to quality management, as staff can engage with the material at their convenience, fostering a deeper understanding of the standards they are expected to uphold. Additionally, these platforms often allow for feedback and discussion, creating an interactive environment where employees feel valued and heard.

Incorporating visual aids through technology can also enhance the communication of quality control standards. Digital signage within the warehouse can display key performance indicators, reminders of quality protocols, and even success stories that highlight the importance of maintaining high standards. This visual reinforcement serves as a constant reminder of the organization’s commitment to quality, motivating staff to take ownership of their roles in the process. Furthermore, augmented reality (AR) tools can provide interactive training experiences, allowing employees to visualize quality control procedures in action, thereby improving retention and understanding.

Training programs can also benefit from technological advancements. Virtual reality (VR) simulations can immerse employees in realistic scenarios where they must apply quality control standards in a controlled environment. This hands-on experience not only enhances learning but also builds confidence in their ability to execute quality protocols effectively. By investing in such innovative training methods, organizations demonstrate their commitment to equipping staff with the necessary skills to uphold quality standards.

Additionally, data analytics can play a crucial role in communicating quality control standards. By analyzing performance metrics and trends, organizations can identify areas for improvement and tailor their communication strategies accordingly. For example, if data reveals that certain quality issues are recurring, targeted training sessions can be developed to address these specific challenges. This data-driven approach not only enhances the effectiveness of communication but also empowers employees by providing them with the insights needed to improve their performance.

Ultimately, leveraging technology for effective quality control communication is about creating an environment where every warehouse staff member feels informed, engaged, and empowered. By embracing these technological advancements, organizations can foster a culture of quality that resonates throughout the entire operation. As employees become more connected to the quality control standards, they are more likely to take pride in their work, leading to improved outcomes and a stronger commitment to excellence. In this way, technology not only serves as a tool for communication but also as a catalyst for inspiration and growth within the workforce.

Strategies For Addressing Common Misunderstandings In Quality Standards

Communicating quality control standards effectively to warehouse staff is essential for maintaining high operational standards and ensuring customer satisfaction. However, misunderstandings can often arise, leading to inconsistencies in performance and quality. To address these common misunderstandings, it is crucial to implement strategies that foster clarity and engagement among team members. One effective approach is to utilize clear and concise language when discussing quality standards. By avoiding jargon and overly technical terms, managers can ensure that all staff members, regardless of their background or experience, fully comprehend the expectations set before them. This clarity not only helps in reducing confusion but also empowers employees to take ownership of their roles in the quality control process.

Moreover, visual aids can play a significant role in bridging the gap between understanding and application. Incorporating diagrams, flowcharts, and checklists into training materials can provide a visual representation of quality standards, making them more accessible and easier to remember. When employees can see the standards laid out in a straightforward manner, they are more likely to internalize the information and apply it effectively in their daily tasks. Additionally, regular training sessions that include hands-on demonstrations can further reinforce these standards. By engaging staff in practical exercises, managers can illustrate the importance of quality control in real-world scenarios, thereby enhancing retention and understanding.

Another strategy involves fostering an open dialogue about quality standards. Encouraging warehouse staff to ask questions and express concerns creates an environment where misunderstandings can be addressed promptly. This two-way communication not only clarifies expectations but also builds trust between management and employees. When staff feel comfortable voicing their thoughts, they are more likely to engage with the quality control process actively. Furthermore, recognizing and addressing common misconceptions directly can help dispel myths that may hinder compliance. For instance, if employees believe that quality control is solely the responsibility of a specific team, it is vital to communicate that everyone plays a role in maintaining standards.

In addition to these strategies, providing regular feedback is essential for reinforcing quality control standards. Constructive feedback helps employees understand where they excel and where improvements are needed. By celebrating successes and addressing areas for growth, managers can motivate staff to strive for excellence. This ongoing feedback loop not only clarifies expectations but also fosters a culture of continuous improvement, where quality is seen as a shared responsibility rather than a checklist to be completed.

Furthermore, recognizing the contributions of warehouse staff in maintaining quality standards can significantly enhance their commitment to these practices. Acknowledging individual and team efforts through rewards or public recognition can inspire a sense of pride and ownership in their work. When employees see that their efforts are valued, they are more likely to adhere to quality standards and encourage their peers to do the same.

Ultimately, addressing common misunderstandings in quality control standards requires a multifaceted approach that combines clear communication, visual aids, open dialogue, regular feedback, and recognition. By implementing these strategies, warehouse managers can create an environment where quality is prioritized, understood, and embraced by all staff members. This commitment to quality not only enhances operational efficiency but also fosters a culture of excellence that resonates throughout the organization, inspiring everyone to contribute to a shared vision of success.

Q&A

1. Question: What is the primary goal of communicating quality control standards to warehouse staff?

Answer: The primary goal is to ensure that all staff understand and adhere to the quality standards necessary to maintain product integrity and customer satisfaction.

2. Question: What methods can be used to communicate quality control standards effectively?

Answer: Methods include training sessions, written manuals, visual aids (like posters), regular meetings, and digital communication platforms.

3. Question: How often should quality control standards be reviewed with warehouse staff?

Answer: Quality control standards should be reviewed regularly, ideally quarterly, and whenever there are updates or changes to procedures.

4. Question: What role does feedback play in communicating quality control standards?

Answer: Feedback allows staff to express concerns, ask questions, and suggest improvements, fostering a culture of continuous improvement and engagement.

5. Question: How can visual aids enhance the understanding of quality control standards?

Answer: Visual aids can simplify complex information, provide quick reference points, and reinforce key messages, making it easier for staff to remember and apply standards.

6. Question: Why is it important to tailor communication to different roles within the warehouse?

Answer: Different roles may have varying responsibilities and levels of understanding, so tailored communication ensures that each staff member receives relevant information that they can apply effectively.

7. Question: What is the impact of effective communication of quality control standards on overall warehouse operations?

Answer: Effective communication leads to improved compliance with quality standards, reduced errors, enhanced efficiency, and ultimately better customer satisfaction and business performance.

Conclusion

Effectively communicating quality control standards to warehouse staff is essential for ensuring product integrity and operational efficiency. Clear, concise messaging, combined with regular training and accessible resources, fosters a culture of quality awareness. Utilizing visual aids, hands-on demonstrations, and feedback mechanisms enhances understanding and compliance. Ultimately, a well-informed workforce is crucial for maintaining high standards, reducing errors, and improving overall productivity in the warehouse environment.

Misunderstandings Training Culture of Quality Awareness Feedback Mechanisms Visual Aids

Leave a Reply